centrifugal hydrocyclone|hydrocyclone function : chain store The following parameters are decisive for good cyclone operation:• the design• the . See more The Flight built-in ultrasonic Piezo Scaler is a compact yet powerful machine used to remov.

{plog:ftitle_list}

To avoid recontamination, packages must be dry after completion of the drying cycle when they leave the sterilizer and remain intact until the instruments are next used. A ‘wet pack’ has moisture on or in the pack when removed from .

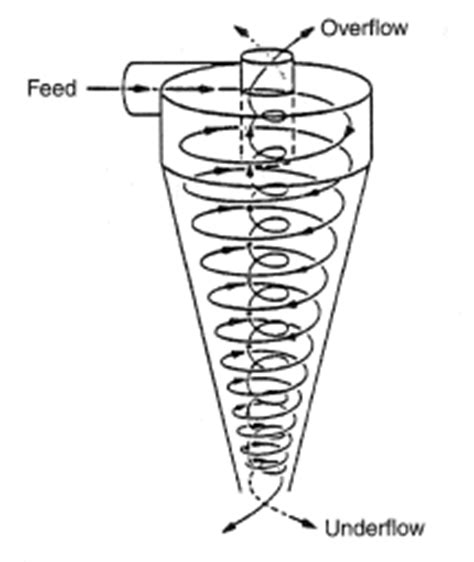

Hydrocyclones are a type of cyclonic separators that separate product phases mainly on basis of differences in gravity with aqueous solutions as the primary feed fluid. As opposed to dry or dust cyclones, which separate solids from gasses, hydrocyclones separate solids or different phase fluids from the . See moreProduct is fed into the hydrocyclone tangentially under a certain pressure. This creates a centrifugal movement, pushing the heavier phase outward and downward alongside the wall of the conical part. The decreasing . See moreThe main areas of application for hydrocyclones are:• Mineral processing industry Hydrocyclones are frequently utilized in the metallurgical and mineral processing industry for the classification of fine particles and . See more

The following parameters are decisive for good cyclone operation:• the design• the . See more

The hydrocyclone is a simple piece of equipment that uses fluid pressure to .The hydrocyclone, also referred to as cyclone, is a classifying device that utilizes centrifugal .

In general, cyclones use centrifugal force to separate particles in a gas or liquid stream. In .

Hydrocyclones, otherwise known as centrifugal cleaners, vortex cleaners, or centricleaners, . Hydrocyclones, otherwise referred to as cyclones, are mechanical separation . This paper presents a comprehensive state-of-the-art review of the .

Hydroclone is a type of equipment to classify materials according to the ratio of . Hydrocyclones are commonly used rotary flow separation and classification . Cyclones, which use centrifugal force to separate a continuous phase from a dispersed phase, are the predecessors of hydrocyclones. When the primary phase is a liquid, it becomes a hydrocyclone. Hydrocyclones can, .

Hydrocyclones are essentially simple devices that convert pressure generated by a centrifugal pump into centrifugal force, causing suspended solids in the mud to be separated from the fluid. This separation is actually accelerated settling due to the increased gravitational force caused by the centrifugal action inside the cone.In general, cyclones use centrifugal force to separate particles in a gas or liquid stream. In hydrocyclones, the liquid is the fluid medium. There are two design classifications for cyclones. Uniflow or swirl tube cyclones are designed so that the clean gas or liquid leaves the cyclone in the same direction that the inlet gas flows.Due to the presence of centrifugal forces, a hydrocyclone could be confused with a centrifuge. There are no moving parts in a hydrocyclone and the size of the centrifugal force is around 1000 times greater than gravity. A centrifuge is a dynamic device with moving parts whereby the generated centrifugal force is greater than that generated in a .

A hydrocyclone is a conical equipment, which employs centrifugal force produced by pressured flow to separate solids and oil particles from oily wastewater, depending on their density difference (Fig. 15).They typically feature a conical base and a cylindrical top section where the liquid is fed tangentially. Pressurizing the intake flow induces cyclonic development in the middle of the . Hydrocyclones are centrifugal devices used to perform the sepn. of a discrete phase (solid or liq.) from a continuous one. Depending on the process goal, particle classification, or thickening, it is possible to enhance the performance of these devices by optimizing their geometric relationships. In this study, innovative geometric .

Hydrocyclones, otherwise referred to as cyclones, are mechanical separation devices that utilize centripetal or centrifugal forces within a vortex in order to sort particles present within a liquid suspension. Hydrocyclones, otherwise referred to as cyclones, are mechanical separation devices that utilize centripetal or centrifugal forces .The structure of the hydrocyclone is relatively simple. Its upper end is a cylindrical part, and its lower part is a conical container. The slurry is fed into the cyclone at a certain speed (generally 5 to 12 meters per second) along the tangential direction, and obtains a rotary motion, thus generating a large centrifugal force (usually tens of times or even hundreds of times greater . The vast majority of current research on hydrocyclone field centrifugal separation focuses on low concentration fluids having volume fraction less than 3%. For high-concentration fluids having volume fractions greater than 10%, which are often encountered in engineering, the law governing particle motion and the classification mechanism are still unclear. In order to . Hydrocyclone has a history of about 129 years. It has been used in various industries including mineral, chemical, coal, petroleum, papermaking, environmental protection, soil remediation, waste management, agriculture, aquaculture, food, biotechnology, nanotechnology, material science technology, and thermal energy due to its high separation .

The VorSpin Hydrocyclone Series: Hydrocyclone applications have a wide appeal to engineers and project managers in many industries because of their designed simplicity with no moving parts. The Fields of Industry applications are shown below: . Hydrocyclones use the centrifugal separation principle to remove or classify suspended solids in a .Buy Lakos SandMaster Plus Stainless Steel Centrifugal Separator Sand Removal System for water treatment and filtration purpose online only at Cannon Water or call us at 916-315-2691 for any inquiry. Get it at a discounted price.Hydrocyclones first appeared in dutch in the late 1800s, Hidrociclon is an equipment that uses rotary current to classify, separate or sort coarse particles of sewage. It widely used in mine processing such as aggregates, hard rock mining, sand, industrial minerals, coal and more. . Then under the action of centrifugal force, the coarse and .

Hydrocyclones have been in use in industry since the 1940s, although the first patent can be traced back to the nineteenth century . an outwardly acting centrifugal force and an inwardly acting drag force, as indicated in Figure 2. Particles are separated by the accelerating centrifugal force based on size, shape, and density, while the drag .Hydrocyclone has become widely accepted in the oil and gas industry, with treating capacity of nearly 8 MM barrels of water per day sold to date. This success is largely due to the ability of this . centrifugal pumps to elevate feed pressure is a cost effective option when system pressure is .A hydrocyclone is a separation device that uses centrifugal force to classify particles based on their size and density in a liquid medium. By forcing the liquid through a cylindrical vessel, the hydrocyclone creates a vortex that allows heavier particles to settle towards the bottom while lighter particles are carried away with the overflow.

Hydrocyclone separators, sometimes called enhanced gravity separators, use centrifugal force to remove oil droplets from oily water. As shown in Figure 7-16, static hydrocyclone separator consist of the following four sections: a cylindrical swirl chamber, a concentric reducing section, a fine tapered section, and a cylindrical tail section. The mathematical model of separation of inhomogeneous fluid systems in centrifugal force field is adapted to viscoplastic fluid purification in a cylindroconical hydrocyclone by pressure flotation process. The model takes account of the action of inertial and Coriolis forces and associated mass of fluid. The system of partial differential equations describing the .

A hydrocyclone is a simple cone-shaped cylindrical container that has no moving parts. It is used to separate or “cut” solid particles in a liquid stream by size and density. . creating a swirling motion inside the cyclone cylinder which throws the solids to the outside of the cylinder by centrifugal force. The larger particles move .Hydrocyclones operate under pressure. Fluid is directed tangentially into the hydrocyclone which causes it to spin. The spinning motion generates strong centrifugal forces which induces the solid and liquid, or the two immiscible liquids, to separate. The centrifugal force generated in a hydrocyclone varies over its length, and may reach a . Hydrocyclone batteries enable the separation of anammox and ammonia oxidizing bacteria, and retaining higher-mass flocs in the system, which leads to the emergence of granular sludge with very good settling properties. . Studies show that the motion of particles in hydrocyclones is governed mostly by the drag force and centrifugal force while . Hydrocyclones are a type of centrifugal separation equipment widely employed in mining [1], [2], chemical [3], [4], coal and petroleum [5], [6], environmental [7], [8], agriculture and aquaculture [9], [10], and food [11], [12] industries. These separation units benefit from their simple geometric structure, no moving parts, low manufacturing cost, and simpler operation and .

hydrocyclone & packed vessels SWECO Hydrocyclone Systems provide an economical and effective method for removing solid particles in the 4 to 100+ micron range from various slurries. Hydrocyclones typically make finer separations than are practical with screening separators and at significantly higher capacities.Hydrocyclone filter is the primary choice in the following situations: . Maximum protection: Conical shape accelerates the velocity of the water increasing centrifugal forces and maximizing separation; Industry leading: UV/Corrosion protection thanks to special two layers coating; The tangential velocity is the premise of centrifugal inertial forces and therefore plays a significant role in the three-dimensional velocity of the hydrocyclone. It can be seen from Figs. 11 and 12 that as the feed solid concentration increases, the tangential velocity of the cylindrical part and the cone part is substantially symmetrically .

spiral flow of a hydrocyclone

Mini-hydrocyclones’ higher centrifugal force results in a higher separation or classification efficiency and smaller cut size (particle or droplet size with a 50% separation efficiency) [53], [55], [56]. Therefore, the use of MHCs has expanded to some new sectors which involve fine particle or droplet separation [57] (Table 1).Semantic Scholar extracted view of "The effect of drag reducing agents on the centrifugal efficiency of a 10mm hydrocyclone." by B. Dabir et al.

hydrocyclone wikipedia

hydrocyclone process

1. Autoclaving is not effective at eliminating RNase in solution because the RNases simply renature as the solution cools.Autoclaving and microwave treatment for as little as 20 sec destroyed the infectivity of all four viruses.

centrifugal hydrocyclone|hydrocyclone function